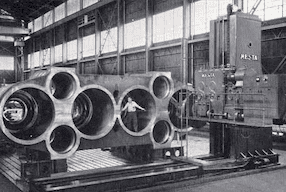

Metal Working Equipment Marketing Plan

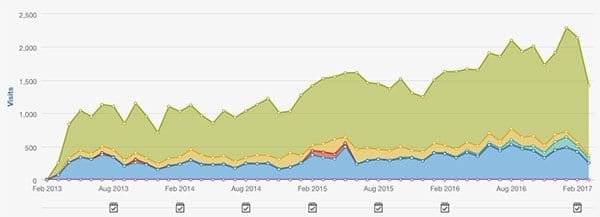

To ThomasNet or not to ThomasNet, that is the question. Hmm, it means blogging to the rescue! ThomasNet, or Thomas Register as it was called years ago, has become a Platinum Hubspot resaler. It's not much of a directory any more since…